Introduction

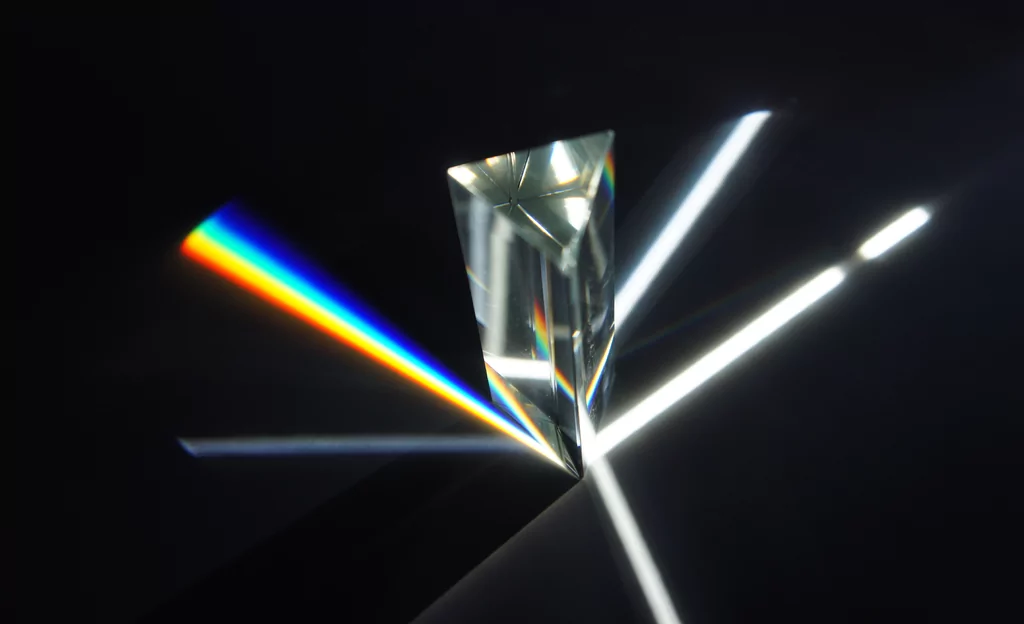

One of the most common images for any that has study optics is that of Sir Isaac Newton with a beam of white light going through a glass prism and a rainbow coming out on the other side. It is one of the most famous optical experiments, not only for its simplicity, but also because it helped Newton set the foundations for his corpuscular theory of light.

That small prism that Newton was using is just one of many applications that prisms have in many optical systems. In the article we will try to describe the four types of prisms: Dispersive (like the one Newton was using), Reflective, rotation and displacements. As well as some consideration on the manufacturing of prisms.

Dispersive prisms

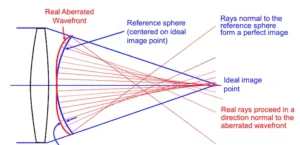

A dispersive prism is an optical element used to break up light into its different wavelength components – a phenomenon discovered by Sir Isaac Newton. By doing this, the prism separates light of varying wavelengths, with longer wavelengths (red) deflecting at a lesser angle than the shorter ones (violet). This phenomenon occurs because the prism’s refractive index varies by the wavelengths of the light.

The design of a dispersive prism is critical to its functionality and can significantly impact the quality of the light separation. This article will discuss essential parameters for designing a dispersive prism and provide guidelines for creating an effective and efficient device.

Among the parameters that we need to take into consideration when designing a dispersive prism are:

- Material Selection: The first consideration in designing a dispersive prism is the choice of material. The material used for the prism should have a high refractive index, as this will determine the extent of the bending of light as it passes through the prism. Common materials used for dispersive prisms include glass and quartz, which have high refractive indices and are transparent.

- Prism Shape: The shape of the prism is also an important factor in its design. The most common shape used for dispersive prisms is the triangular prism, as this shape allows for the maximum bending of light and provides the highest degree of separation. However, other shapes, such as the rhomboid or the pentagonal prism, may also be used, depending on the application’s specific requirements.

- Angle of Incidence: The angle of incidence, or the angle at which light enters the prism, also plays a critical role in the performance of the prism. A larger angle of incidence will result in a higher degree of light bending, leading to a more pronounced separation of the light into its component colors. It is important to optimize the angle of incidence for a given application to achieve the best results.

- Size of the Prism: The size of the prism will also affect its performance. A larger prism will generally result in a higher degree of light bending and a more pronounced separation of the light. However, larger prisms may also be more cumbersome and less practical for some applications. It is important to balance the size of the prism with its performance to achieve the best results.

- Coating: Finally, it is important to consider the coating of the prism, as this can have a significant impact on its performance. The coating should be optimized for the specific application and should be designed to minimize the amount of light loss and scatter. Anti-reflective coatings are common for dispersive prisms, as they help to reduce the amount of light lost as it passes through the prism.

Dispersive prisms are used in a variety of scientific and technical applications, such as spectroscopy, where they are used to analyze the composition of materials based on their spectral signature. They are also used in optics and telecommunications, where they can be used to control the dispersion of light and correct chromatic aberration in lenses.

The dispersion of a prism is typically measured as the angular separation between two spectral lines of a particular wavelength. The following formula, which assumes a thin-prism, can be used to calculate the dispersion of a prism:

D = (n – 1) * A

where:

D = dispersion of the prism (in degrees)

n = refractive index of the prism material

A = apex angle of the prism (in degrees)

In conclusion, designing a dispersive prism involves considering several critical factors, including the choice of material, the shape of the prism, the angle of incidence, the size of the prism, and the coating. By carefully considering these factors, it is possible to design an effective and efficient dispersive prism that provides high-quality light separation.

Reflective prisms

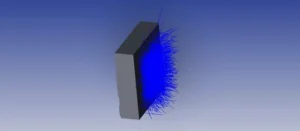

Reflective prisms can be used in imaging systems. Due to the total internal reflection, light entering the prism can undergo multiple reflections until they reach an output face. It is possible to add a reflective surface so the prism behaves as a beam splitter. Reflective prisms are used to reduce the physical size of an optical system, to redirect the direction of light, and to reform the orientation of an image.

Reflective prisms present lower optical power losses than equivalent systems made with mirrors and are usually easier to align due to the fact that a single element is used instead of several.

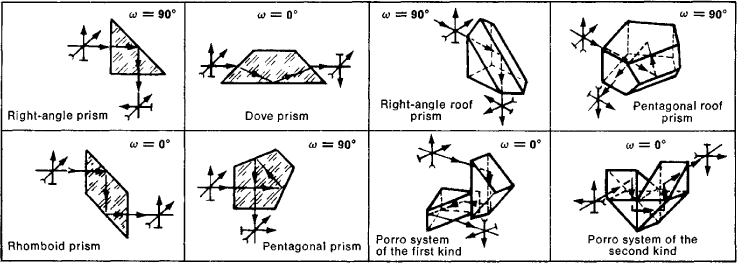

Figure 1 shows one of the most common reflective prisms geometries. In general, if the number of reflective faces is even, we will be creating an upright image, while an even number of reflective surfaces will create an inverted image.

Different types of prisms and configurations

Right angle prisms are usually used to deviate the direction of light by 90-degrees. It’s possible to use a right angle prism in a Porro configuration when light is incident through the prism’s hypotenuse. Light will be deflected 180-degrees and flipped.

Dove prisms are right angle prisms with their top part removed. They can be used to invert images. It is possible to coat the side where light is reflected for optical sensing applications.

Right-angle roof prisms are usually used in binoculars or when a right angle deflection of an image is required. The image is deflected left-to-right not top-to-bottom.

A pentagonal roof prism, deviates the beam 90-degrees without deflection left-to-right or top-to-bottom.

Rhomboid Prisms create an output beam that is displaced from the input beam, but it doesn’t change the direction of the beam, nor does it invert the image.

Porro prisms (either stand-alone or in higher-degrees configurations) are usually used to change the orientation of an image. They are usually used as erectors in optical instruments like binoculars, telescopes, and microscopes where there are space restrictions. The degree of a porro system will depend on how many axes the image needs to be altered in

Wedge prisms: Have a shallow angle and can be used together for beam steering in a Risley prim pair

Anamorphic Prisms

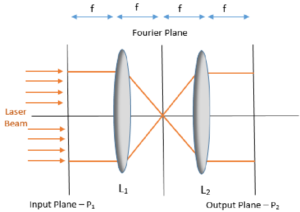

An interesting application of prisms is the change of the incident beam dimensions. This is caused exclusively by the geometry of the prism (e.g. the angle of the incident vs refracted faces), and not the focusing elements or collimating effects like in a lens. Anamorphic lenses are usually configured in pairs to keep the beam traveling along the optical axis.

Manufacturing

The manufacturing of prisms usually involves several steps. Starting with the chosen glass, a series of cuts are done to form a basic prism shape. This stage usually ends in a rough draft of the final product. The prism will have the shape requested but of poor optical performance.

After that, a series of polishing and smoothing steps of the optical surfaces are needed. This can take several iterations depending on the optical tolerances requested by the client and their application. At this stage, antireflection coatings, filters, and metallic layers can be added to achieve the required performance.

A technician is in charge of supervising and evaluating each stage. Some prism geometries can be bought off-the-shelf but for specific applications or custom made optics, it usually requires a considerable amount of time for testing and manufacturing.

Please let us know in the comments if you have had the need to use custom prisms and what was your application.