One parameter that can be used to evaluate the quality of a laser beam is what’s called a Beam Caustic. A caustic, in general, is an “envelope” that defines the extent of a beam of light after they have been refracted (or reflected ) by a curved surface. As the light beams propagate they cross and overlap, creating a series of brightly focused lines on the. For example the bright pattern of twinkling light rays often seen at the bottom of a swimming pool. (Figure 1).

However, caustics have a practical application beyond the creation of interesting patterns. The Laser Beam Caustic is the envelope that limits the extension of the Gaussian beam. This is particularly important in industrial application where lasers are used as a replacement of mechanical drills to cut, and weld different materials.

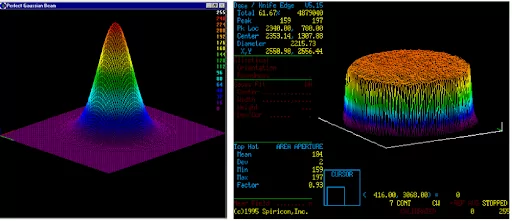

If the focused shape of the laser beam can be analogous to the shape of the drill bit, the caustic could be analogous to the sharpeness of the drill bit. A well defined caustic, where the beam intensity rapidly declines, will create a sharper cut than a laser beam with the same intensity, but less not well defined caustic. For example, a Gaussian beam and top-hat laser beam may have the same focused beam size, but their caustic will be completely different.

Measuring Beam Caustic.

Measuring laser beam caustic can be complicated because it is often used to measure lasers with high power. The intensity is high enough that they can destroy measurement instrumentation. Adding beam-splitter to separate the beam is possible but needs to be done carefully to avoid destruction of the optical elements.

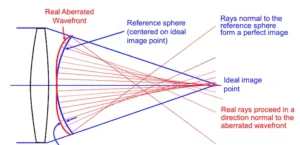

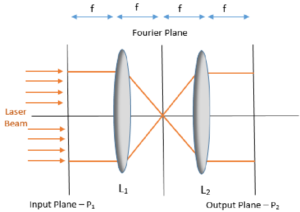

Different techniques to perform caustic measurement include using a Hartmann-Shack wavefront sensor (HSWFS). Typically a pinhole or microlens array is used to monitor the gradient of the wavefront. From this information the actual shape of the wavefront can be computed.

However, disadvantages include the typically low spatial resolution, which is limited by the spacing of its resolving elements. Another technique used variations of defocus techniques combined with wave propagation modeling to obtain wavefront estimates. While such methods work well for near-Gaussian beams, they have limitations for more complex beams.

There are different commercial solutions to measure the quality of the laser beam. Beam profilers can give you a series of measurements in a few seconds. There are several solutions based on CMOS cameras, knife-edge techniques or pinholes. In addition they can measure light intensity and several other parameters. Some examples of commercial beam profilers can be found here: Newport Beam Profiler

Learn more about the unique properties of lasers in these recent posts Laser Rayleigh Range: A Detailed Explanation and M squared and designing laser beam optics