Freeform lenses (including TIR lenses) and lightpipes are the two most common types of LED illumination optics. They can be made using injection molding and are affordable. Glass materials are not common for general illumination, but are used for spherical lenses or aspheres in devices such as optical instruments with Abbe or Köhler illumination.

In this article, we have selected the best materials for LED illumination optics. The “top 5” list shown below is compiled based on our experience with frequently used plastics. The materials are rated according to their optical and mechanical properties, manufacturability, and cost.

5. Silicone resins

The list starts with optical silicone resins, a new optical material with several advantages over widely used PC and PMMA. They have a wide range of applicability, ranging from water sterilization and microscopy illumination to exterior automotive applications. They are also often used as LED lens material. Their advantages include:

- higher UV yellowing stability – high temperatures and high UV exposure without yellowing;

- higher temperature resistance – temperature resistance is below PMMI plastics, it can withstand a rather formidable 150°C;

- high impact and chemical resistance – suitable for industrial application and outdoor machinery, it resist acids, bases, solvents, chemicals, oils, and water;

- low viscosity – allows the resin to fill the mold with ease, enabling us to produce products with intricate shapes. Smaller parts, such as microarrays, can be produced with ease;

- biocompatibility – silicone is appropriate for use in contact with the human body

- Transmission more than 90% up to 350 nm

- Allows optical designs that use thicker parts rather than polymer

- Better impact resistance than polymers

- Very accurate reproduction of detailed shapes and features, such as optical surfaces, sharp edges, and small radii

Optical silicone resins are still not as widespread as PMMA or PC, but their popularity is increasing quickly, especially in UV and medical applications.

4. PMMI (polymethacrylmethylimid)

The fourth place belongs to PMMI (trademarked as Pleximid), “PMMI plastic.” It is plastic rather similar to PMMA and has one distinct advantage:

- very high softening temperature – with a softening temperature of about 170°C. PMMI is primarily used for applications involving heavy thermal loads;

- high optical quality;

- wear and UV resistant.

As seen above, its key characteristic is high thermal resistance, which makes it suitable for the production of high performance/brightness lenses.

3. Zeonex

Zeonex materials, designed by Zeon company, hold the third place. Zeonex is a type of cyclo-olefin copolymers, combining glass and polymer properties. The recognizable Zeonex characteristics include:

- very low water absorption – when compared to PC and PMMA, Zeonex has significantly lower water absorption which makes it dimensionally stable regardless of humidity;

- high molding precision – it is possible to create very small and very thin lenses, making it suitable for applications in modern electronic devices;

- biocompatible – the material is suitable for medical applications.

Other interesting properties include high light transmission, low yellowing (under UV exposure), high thermal resistance (softening temperature between 130°C and 150°C), low birefringence and high Abbe number, and good chemical resistance. Unfortunately, despite excellent optical and mechanical properties, Zeonex has one central disadvantage – much higher cost.

2. PC (polycarbonate)

The second place within the plastic materials group belongs to polycarbonate (PC), which is known by the brand names Macrolon and Lexan. When compared to PMMA, PC is:

- more scratch-resistant – its hardness makes it have significantly lower wear;

- easily molded – decreasing the manufacturing complexity and costs;

- very low UV transmission under 400 nm – it is widely used for outdoor sports safety eyeglasses.

Furthermore, PC has a higher refractive index, lower water absorption, and higher softening temperature than PMMA (130°C). Its otherwise perfect score is diminished by yellowing under prolonged UV exposure and, most importantly – the absence of biocompatibility. Polycarbonate is toxic and thus unsuitable for biomedical applications.

1. PMMA (polymethylmethacrylate)

Finally, with the top pick, PMMA, also known as acrylic, Plexiglass, and Acrilite brand names, is the most widely used plastic material. The first place is won by the following advantages:

- low cost – making it very affordable;

- ease of molding into any shape;

- high light transmission – 93 % as compared with 88% for Polycarbonate;

- “green” material – it is recyclable and BPA free;

- high UV transmittance.

PMMA is widely used for total internal reflection (TIR) lenses. It should be noted that some disadvantages are reported, such as yellowing under prolonged UV exposure, higher water absorption, and lower scratching and heat resistance when compared to other plastics.

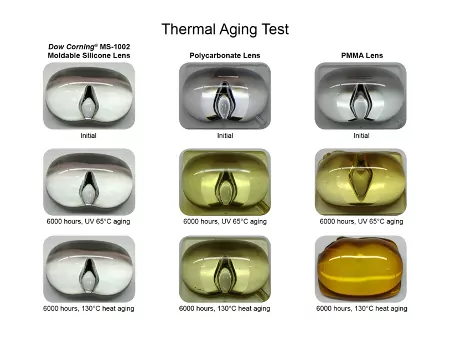

This test image above shows Methyl Silicone, a Dow Corning® MS-1002 and MS-1003 material

and Poly Carbondate and PMMA aging. Source: Dow Corning

Finally, it should be noted that there is no “best” material. The optimal’ material will be highly dependent on the given application and associated technical requirements. Thus, optimal material will not be the same for medical, consumer, industrial, or scientific applications.

Want to learn more about LED optics? This post explaining the physics of TIR lens might be of interest

Need assistance designing a custom illumination optic, lens or light pipe? Learn more about our design services here.