When integrating off the shelf lenses into optical systems, it is essential to have full information about how a lens will perform with other elements in the system. When multiple component vendors ( ie electronics, mechanical, optical) are involved, data needs to be shared without revealing key intellectual property.

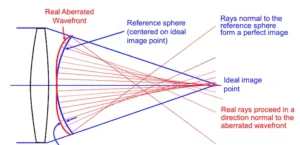

The information found on a traditional datasheet is generally not enough for correct optical design because it does not provide aberration analysis and is therefore not suitable to evaluate image formation. For this reason, Zemax’s OpticStudio offers what is called a “Black Box Lens”.

A black box lens provides all the necessary information to evaluate an optical system without details about the optical design proper. A user can add or modify any element before or after the black box lens and do ray tracing and evaluate aberrations without seeing or being able to modify the design inside the black box.

The black box file benefits both parties: while protecting the IP of an OEM lens supplier, it provides a lens integrator with information they need to make a proper design.

Creation of a black box

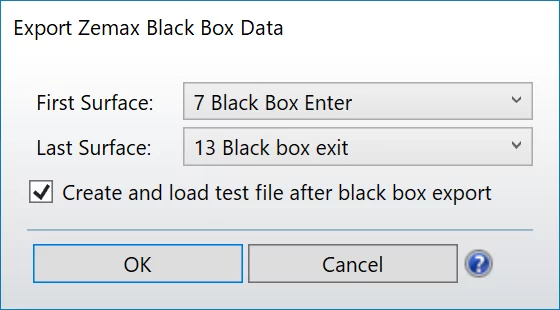

In Zemax, a black box design can be made after the optical design is finished. Once the design is finished the optical engineer adds two dummy surfaces (one at the beginning and one at the end) as a way to “frame” the design. You can find the black box tool under File–>Export menu.

If you have the “Create and load test file after black box export” checked, once the black box is created, it will be replaced in your design and a new file (with a _BB termination added) will be created. This can help you to confirm that the black box is actually behaving as intended.

There are some consequences of using the black box. For example, due to the fact that the lens information is hidden inside the black box, it cannot be accessed for evaluation, optimization, or for any kind of general analysis. Similarly, no ray data is created for any of the elements inside a black box. It is possible to have decentered, tilted, or changed coordinates inside a black box, but it is important that the first and last surface be within the same coordinate system.

Using a Black Box

Let’s say, for example, that we need to design an industrial endoscope for pipeline examination. We want to include a digital camera at the distal end (farthest away from the operator) of the device. In order to minimize cost, it is decided to use off-shelf components. For this example, we assume that we want to use the Microvideo lens camera 59-776 from Edmund Optics (this is just an example, this lens is bigger than the standard diameter for most medical endoscopes, and further evaluation for mechanical resistance needs to be evaluated.)

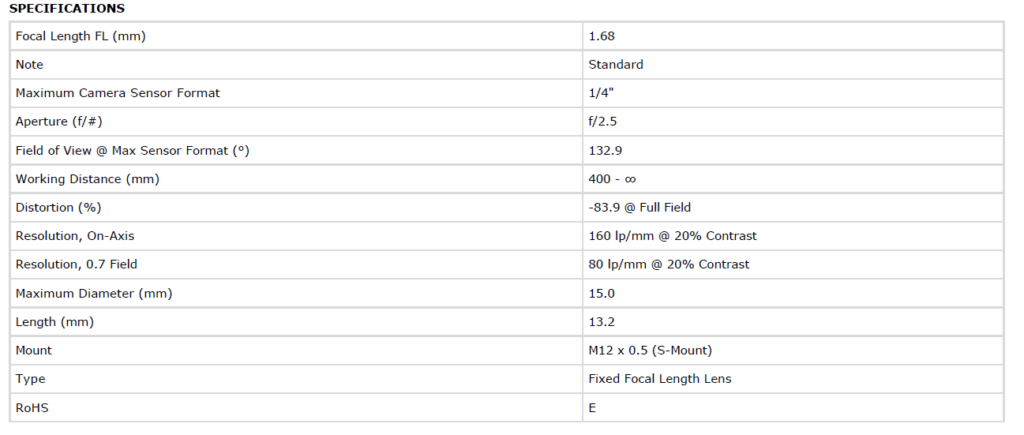

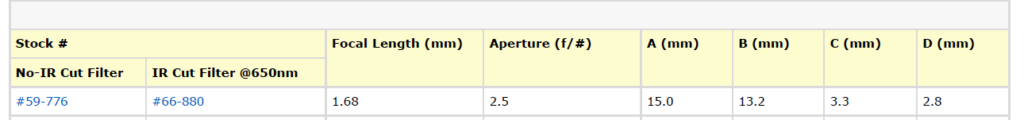

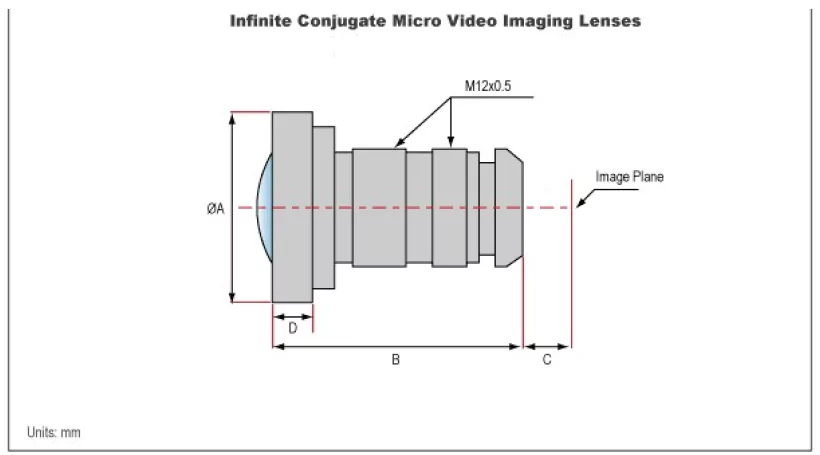

When we go to Edmund Optics product website, we obtain the following technical information:

This is minimum information that can help us do a first draft for the design. It gives us some focal plane parameters without offering a way to evaluate for chromatic aberrations, distortion (although they have a value for that), astigmatism, or any aberration whatsoever.

We could try to approximate these numbers with a couple of lenses so we can have the same focal length, field or view, but that’s not really acceptable, and because this is a proprietary design, we cannot have the details of the lens system. So unless you are ready to disassemble the lens and evaluate and measure every single component, you have no options other than write an email to customer service and request the Zemax Black Box file of the component.

(Note: read our post about why reverse engineering a lens usually not worth trying)

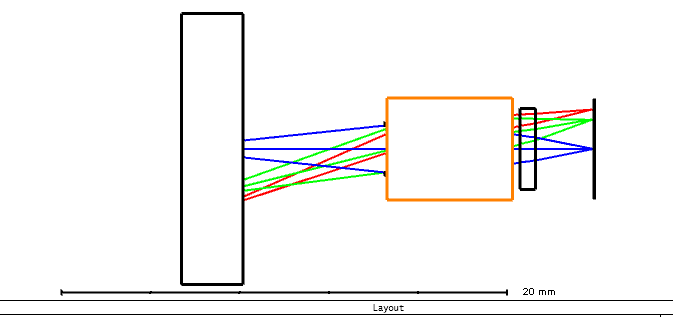

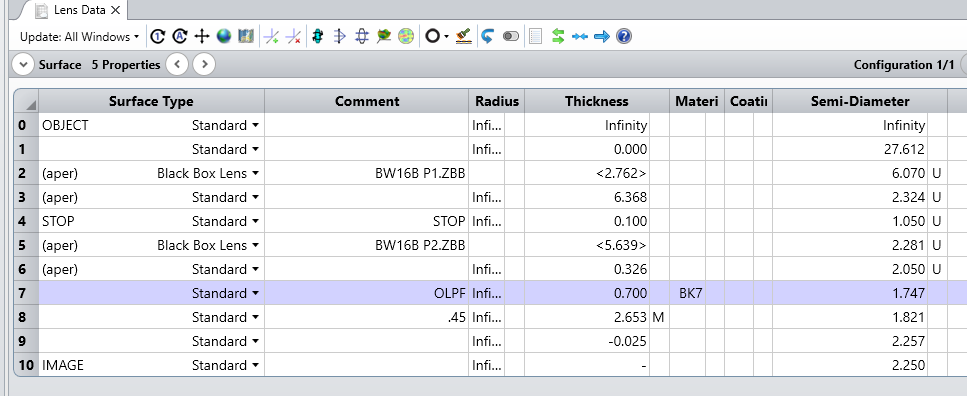

You can include the file in any of your designs. For example in Figure 3, we have used two black-box lenses in our design. You can see that on the lens data, it just appears as “Black Box Lens” and no specific radius or curvature, number of elements, or materials is displayed.

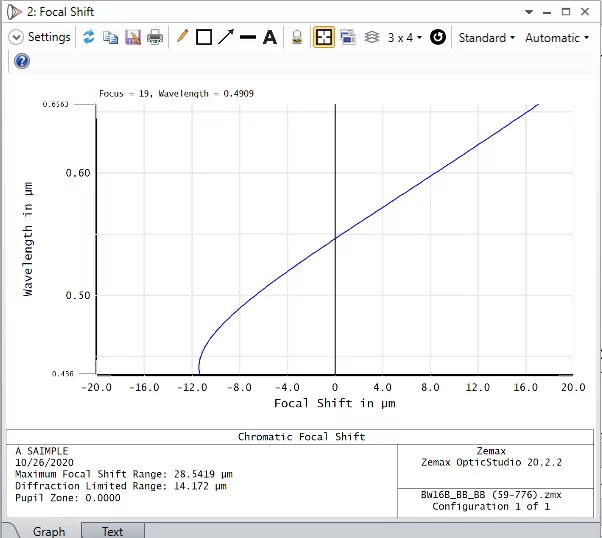

We can however evaluate different aberrations: Figure 4 shows as example the Chromatic Focal shift of this system from 436 nm – 656 nm

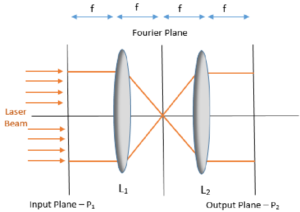

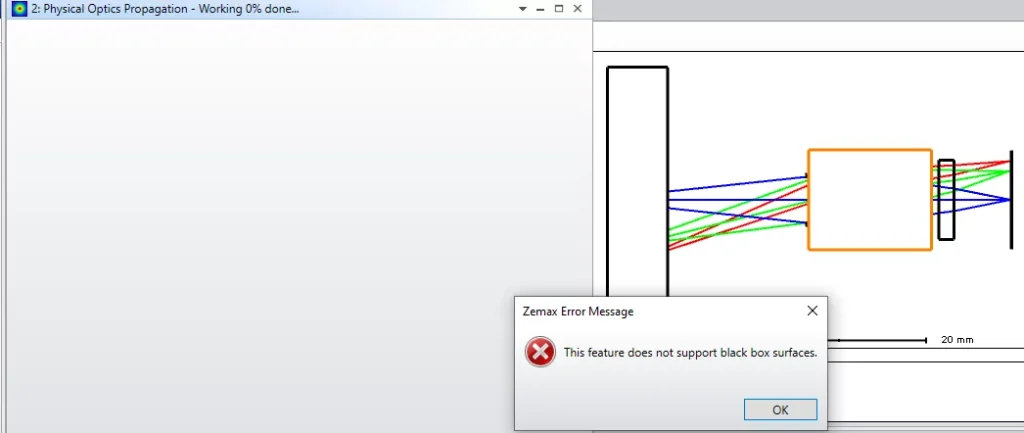

There are some evaluations that are not possible: for example, any physical optics evaluation (in case you are working with anamorphic beams or spatial filters), returns an error message.

Conclusion

Black Box components are a powerful tool necessary when we need to share or work with proprietary components. While we don’t have the ability to manipulate the files, the tool provides very valuable information that would be impossible to obtain otherwise.