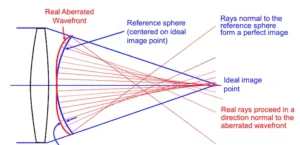

A key aspect of an optical product development is the creation of a quality optical system design optimized to reduce aberrations and system cost. In an attempt to reach a balance between cost and performance, optical designers have created lenses with different shapes that help reduce aberrations. Traditionally, optical elements have radial symmetry: they are symmetric around an axis (usually along the optical axis). This radial symmetry allows manufacturers to produce lenses with spherical, conical, or cylindrical geometry.

Symmetrical spherical lenses can be made of glass or plastic and produced by grinding and polishing, or injection molding. The grinding and polishing production process has been used for centuries and is especially useful for small to mid-sized volume.

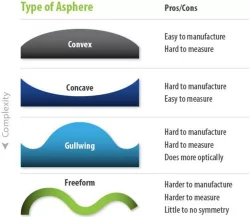

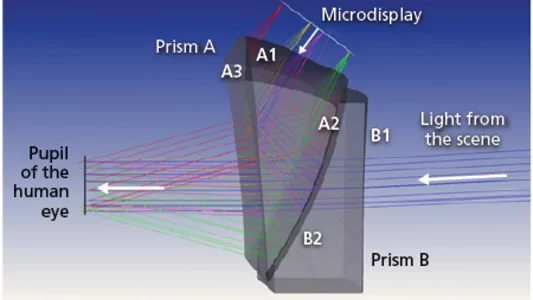

We also have aspheric and freeform lenses whose surfaces have no symmetry around an axis of rotation. They may appear to have an irregular shape and they offer new opportunities and challenges for designers and manufacturers. One of the reasons why freeform optics is so attractive is that it allows designers to simultaneously correct aberrations while increasing Depth of Field. In addition, aspheric lenses can reduce the number of elements needed in an optical system thus reducing system cost.

In most cases, aspheric lenses are produced by injection molding plastic. While there will be a higher upfront tooling cost, the lenses can be manufactured at low cost in higher volume. The small size ( fewer elements) and low cost at very high volume is one reason smartphone camera lenses use aspheric optics.

From Todd Blalock,et al “Fabrication of freeform optics”, Proc. SPIE 9575, Optical Manufacturing and Testing XI, 95750H (27 August 2015);

The concept of freeform optics goes back almost a century, but the first patent was awarded in 1959 to C.W. Kanolt, and the first successful commercial application is the Polaroid SX-70 folding Single Lens Reflex camera released in 1972. The Polaroid SX-70 had a foldable design with a couple of freeform lenses to correct aberrations.

Since 2000, there has been an increase in research and applications of freeform optics. This growth is the result of advances in manufacturing, computer modeling, and an increased need by industry to advance optical design. There are numerous applications of freeform optics in reflective, refractive, and diffractive optical systems. They can be categorized into several areas, such as imaging, illumination, concentration, and other applications.

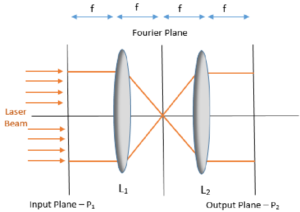

There are several ways to design freeform optics: Zemax, TracePro, and CodeV are three of the leading ones. The way we design a freeform shape is directly in Zemax using user defined objects. We have created a Dynamic Link Library (DLL) where the optical element can be defined using Bézier curves. Here is a conversation with John Ellis and Anatoli Trafimuk, from Optics for Hire, on using Bezier curves to create Freeform optical elements. Their presentation in Envision 2019 can be found here.

Applications

As mentioned earlier, freeform optics used in imaging systems are designed to improve the optical performance by eliminating aberrations and tailor other optical characteristics (e.g depth of field, field of view) to the particular application. An important advantage of freeform optics is that it can reduce the number of optical components and reduce the mechanical complexity of the system assembly.

Freeform optics can be designed to behave in specific ways that traditional optics cannot. For example, Hicks et al. used the freeform reflector as a driver-side mirror for an automobile that gives a field of view up to 45-degrees so that the mirror has no blind spot and minimal distortion. Fraunhofer Institute for Production Technology (IPT) in Germany used a compound eye to design a planar imaging system only 1.4 mm thick.

Non-Imaging Applications

Freeform and aspheric optics have been also used to design non-imaging systems like concentrators and illumination systems. In a concentrator, the goal is to collect the incident light from a large aperture into a small exit. While illuminators create specific patterns or illuminations from specific light sources like LEDs, non-imaging optics are concerned not with image quality but with energy efficiency and distribution.

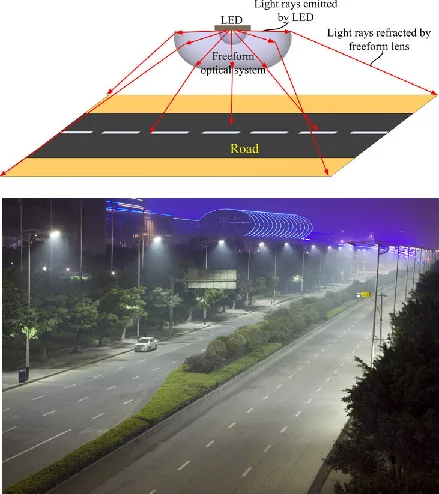

The design of high efficiency non-imaging optical systems requires a different approach from conventional imaging optics. For illumination applications in particular, it is important to control the intensity distribution. Freeform optics provide uniform high quality lighting for LEDs application due to its exact ability to control light.

Combination of an LED and a freeform optical lens for street lighting in Guangzhou, China From “Energy-saving LED light sources,” 30 March 2011, SPIE Newsroom

Conclusion

Advances in manufacturing, metrology, and software are helping optical designers and manufactures to increase the use of freeform lenses. There are still many challenges however that need to be solved including developing better optimization algorithms and modeling systems. Testing for surface quality and managing production tolerances will still limit the production vendor pool and prevent a wider range of applications.