Plano convex lens design is simple compared to many optical systems, but there are fine details that a lens designer needs to pay attention to. Plano convex lenses are lenses with a positive focal length. This is a very common configuration, and a plano convex can be manufactured in different glass types, with different coatings, and can be customized for many applications.

In general, plano convex lenses suffer from chromatic aberration, so they are better for focusing single wavelength light sources or for monochromatic collimations. Nevertheless, it is not unusual to use them for imaging application or in infinite conjugate configurations. Since these lenses are not symmetric, their orientation matters. For most applications you may need to have the flat surface to point towards the image focal plane.

In the article we will talk about three important steps required to design a plano convex lens, some of the points can be applied to the design of any optical system

1. Clarify Requirements

First of all we need to understand the application, and the requirements that we need in our lens (or system). These can be the resolution, wavelength(s), field of view, image size, focal length.

Once we have these requirements we can start with a simple system (first-order approximation) that satisfies some of these requirements. For example, we can set up a simple lens that will create an image of the required size, at the required location, and with the required orientation.

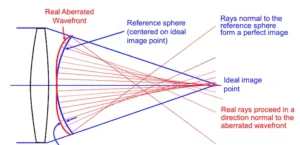

2. Control aberrations

At this point we can start working with some aberrations. It is recommended to start reducing chromatic aberration, but there is a limit of how much chromatic aberration can be reduced in a plan-convex system. If very low chromatic aberration is needed, you may be better off switching to a double achromat configurations. You can try to reduce the Petzval aberration. This most likely will involve changing the curvature of the curved-surface and thus changing the power of the lens. You can try to modify the glass that you are using while changing the thickness of the lens to preserve the right power.

Again, if the final thickness of the lens is too big, or if after several iterations it is not possible to achieve the desired aberrations curves, it may indicate that you need to split your lens in two or more components.

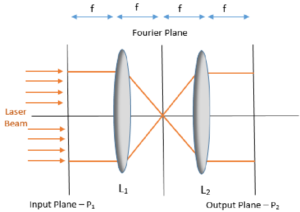

3. Adjust speed and field-of-view

Sometimes it is necessary to increase the speed and/or the field-of-view of a lens. This is common when we try to adapt a previous design to a new application. The field-of-view is limited by the height of the principal rays that can go through the lenses and also because some rays encounter total internal reflection on the lens’ surface. A solution for this problem is to change the stop pupil of the system away from the lens, limiting the height of the principal rays on the lens.

We can then increase the size of the lens so that it can provide the right speed. AS always they is a compromise, our lenses have a size limit, and the stop pupil sometimes is not possible to move.

Conclusion

Lens design is a strange combination of experience, knowledge and it’s to a point an art. We may have guidelines that help us how to start, but the interactive process and evaluation of the different design parameters is almost unique to each optical engineer. This is usually a process with multiple steps that requires constant feedback from the client.