Optical alignment with auto-collimators

The field of optics has witnessed remarkable advancements over the years, enabling the development of increasingly complex and precise optical assemblies. In this pursuit of perfection, engineers and researchers have turned to specialized tools like auto-collimators to ensure the accuracy and alignment of optical components. An auto-collimator is a versatile optical instrument that plays a pivotal role in the assembly, testing, and alignment of optical systems. This article delves into the principles, applications, and benefits of using auto-collimators for optical assemblies.

Principles of Auto-Collimation

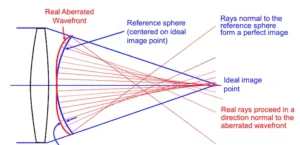

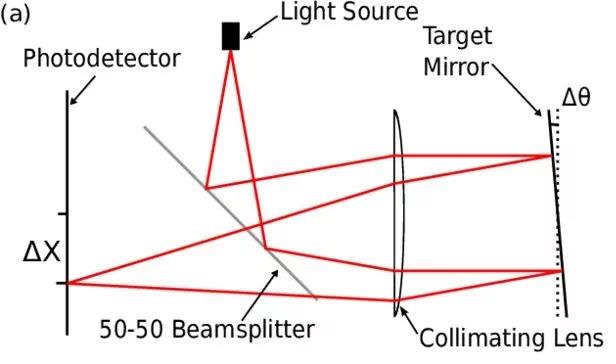

Auto-collimators are based on the principle of collimation, which involves aligning a light source to be parallel or nearly parallel to an optical axis. These instruments typically consist of an optical system, a source of light (such as a light-emitting diode or laser), and a detector (usually a telescope or camera). The heart of an auto-collimator lies in its ability to detect minute angular deviations by measuring the reflected light.

When the collimated light is directed onto a mirror or surface, it reflects back along the same path. If the mirror is perfectly aligned, the returning light will enter the auto-collimator’s optical system and hit the detector. However, any misalignment will cause the reflected light to deviate from its original path, allowing the auto-collimator to measure the angular error. By precisely quantifying these angular deviations, engineers can effectively assess and adjust the alignment of optical components.

Applications of Auto-Collimators

Auto-collimators find a multitude of applications in the realm of optical assemblies:

- Alignment of Optical Elements: In the construction of telescopes, microscopes, cameras, and other optical devices, precise alignment of lenses, mirrors, and other components is paramount. Auto-collimators aid in achieving optimal alignment, leading to improved optical performance and reduced aberrations.

- Lens Centering and Mounting: During the manufacturing process of lenses, auto-collimators are employed to ensure the accurate centering and mounting of lenses within their respective housings. This prevents decentering, which can lead to reduced image quality and resolution.

- Testing and Verification: Auto-collimators serve as valuable tools for quality control, allowing manufacturers to assess the performance of optical components and systems before they are released to the market. Any deviations from the desired specifications can be detected and rectified.

- Angle Measurement: Auto-collimators excel in measuring small angular displacements. This capability is utilized in fields like metrology, where precise angle measurements are essential for calibrating instruments and aligning machinery.

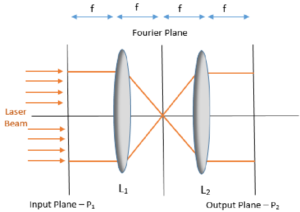

- Interferometry Setup: Auto-collimators are a crucial component in interferometry setups, where they aid in creating interference patterns by aligning optical elements, such as beamsplitters and mirrors, to sub-micron accuracy.

- Vibration and Motion Analysis: Auto-collimators can also be employed in dynamic applications, such as studying the vibration and motion of mechanical components. By tracking angular deviations over time, engineers can gain insights into the behavior of moving parts.

Benefits of Using Auto-Collimators

The utilization of auto-collimators in optical assemblies offers several notable benefits:

- Precision and Accuracy: Auto-collimators are capable of detecting angular deviations down to fractions of an arcsecond, ensuring that optical components are aligned with exceptional precision.

- Time and Cost Efficiency: The use of auto-collimators expedites the alignment process, saving valuable time during the assembly and testing stages. This efficiency translates to cost savings in both manufacturing and research environments.

- Non-Destructive Testing: Auto-collimators enable non-destructive testing, as they do not physically touch the components being assessed. This is particularly advantageous when dealing with delicate or sensitive optical elements.

- Reduced Human Error: Manual alignment processes are susceptible to human error, which can lead to suboptimal performance. Auto-collimators mitigate this risk by providing objective and repeatable measurements.

- Versatility: Auto-collimators are adaptable instruments that can be employed across various optical applications, making them valuable tools in a wide range of industries.

Conclusion

The application of auto-collimators in optical assemblies represents a significant stride in enhancing the precision and performance of optical systems. These versatile instruments play a crucial role in aligning components, verifying quality, and ensuring optimal functionality. As technology continues to push the boundaries of optical capabilities, auto-collimators stand as indispensable tools that empower engineers and researchers to achieve unprecedented levels of precision and accuracy in the realm of optics.