Opto mechanical design overview and definitions

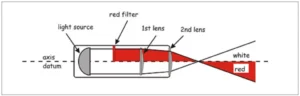

In an opto-mechanical design we work on the positioning of optical elements such as lenses, filters, beamsplitters, reflectors, and diffractive elements in mechanical structures that will allow the optical system to perform correctly.

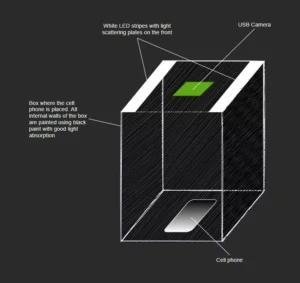

A typical opto-mechanical design package would include:

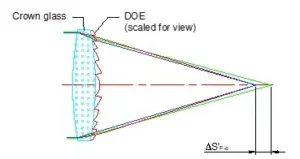

- Drawings of all lens elements. Thes drawings define part geometries and are drafted according to ISO standards (read more about lens drawings here)

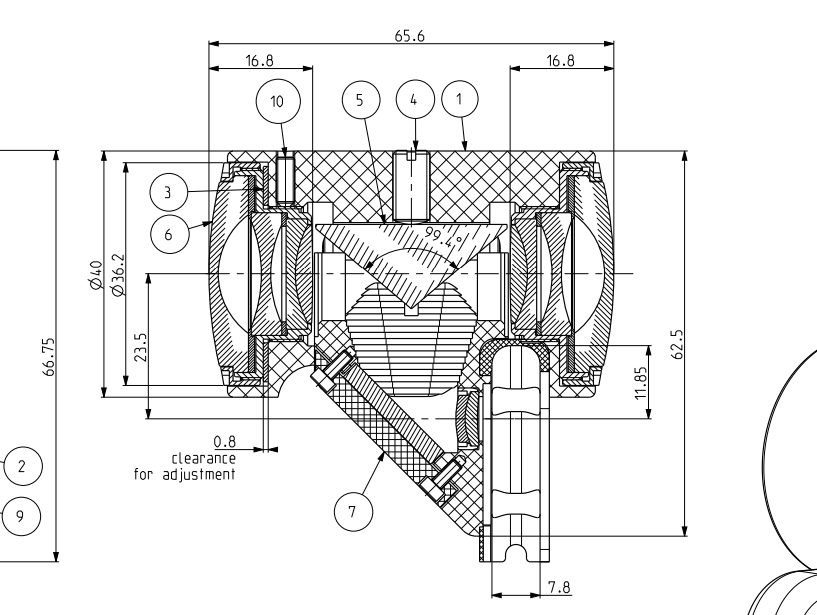

- Layout drawings, such as the one below, showing the full assembly of all the mechanical and optical elements and their individual positional tolerances.

Need assistance designing a custom optic or imaging lens? Learn more about our design services here.

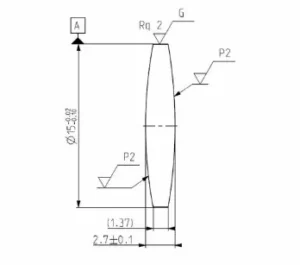

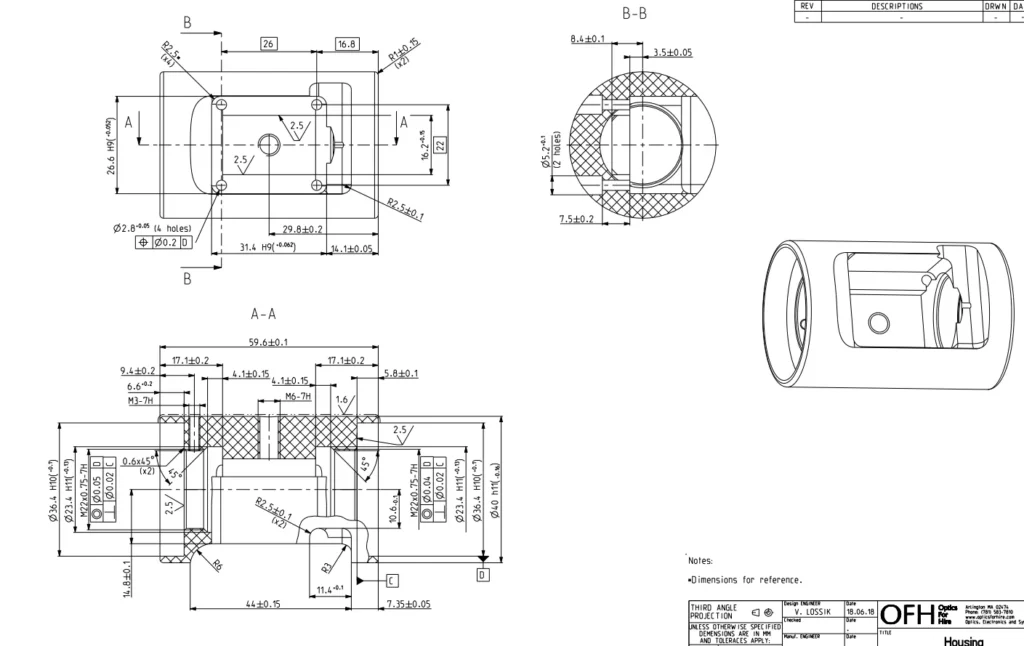

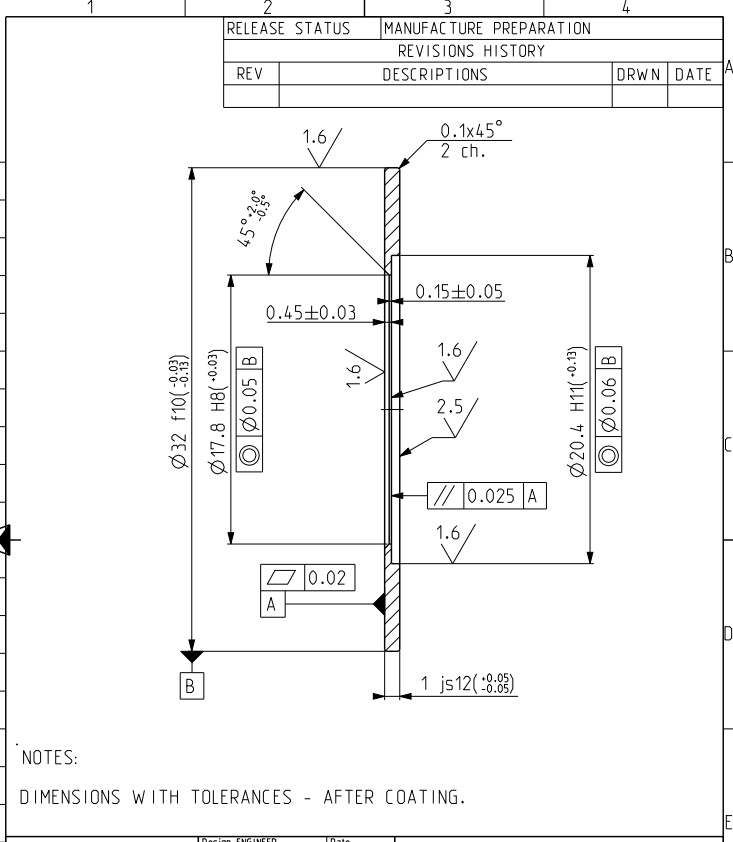

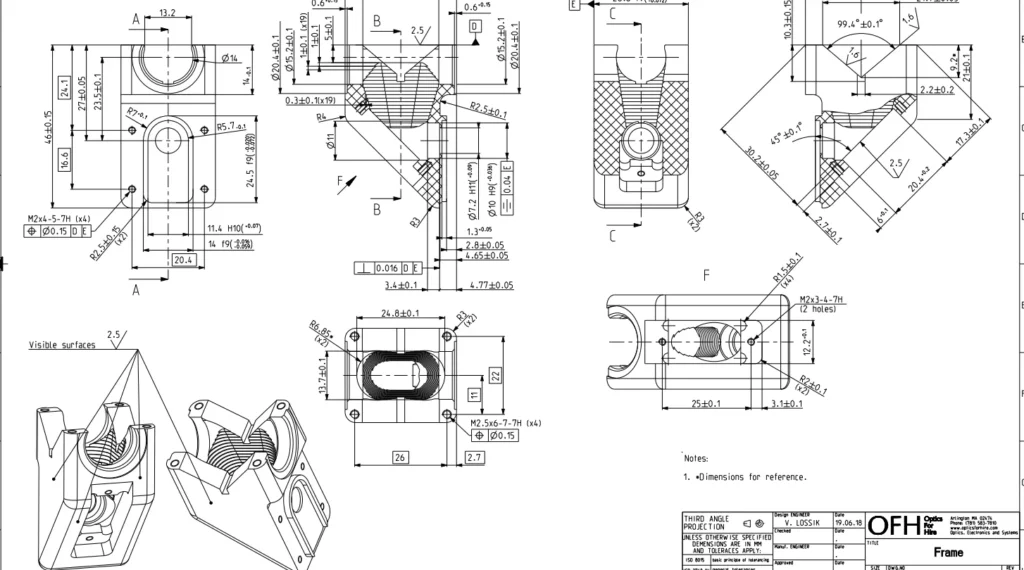

Part drawings, for each mechanical element including spacers, lens barrels, and adjustment mechanics each individual part. One example is a part drawing below; it includes nominal measurements as well as required tolerances. All the part drawings include all the dimensions, tolerances, and symbols needed to produce an object.

Assembly drawings describe the complete opto-mechanical system and provide the information necessary for assembling it. Besides outer dimensions, they include lists of parts the assembly contains and defines the connections between them; even simple mechanical parts in an optical system can require extensive documentation and notations for coatings, materials, and tolerances.

The development of the opto-mechanical design involves extensive input from the lens designer. Tightening lens element tolerances can help relax mechanical and assembly tolerances, while the inverse is also true. Reaching the desired performance with the most robust and easiest to produce optical system is a balancing act.

Example: Zoom lens design

Cam Movement

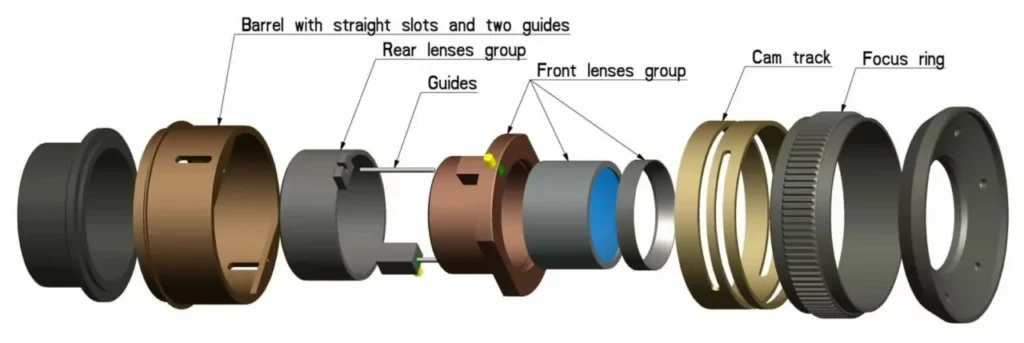

In zoom and focusing systems which have moving elements which require precision positioning relative to one another, opto mechanical design is essential. One typical system is a cam zoom system which includes three main components: a front lens group, a rear lens group and a cam mechanism.

The front lens group is attached into a front carriage and the rear lens group is attached into a rear carriage. Both carriages move along rods fitted into a lens housing parallel to the optical axis.

A typical distance for slider bearings and guide is just 6 to 10 microns (0.00025 to 0.0004 in.). The reason is that with larger clearance, the image can jump causing it to go out of focus when the zoom motion reverses.

Need help? Click here to learn more about our custom optical engineering services.

The smaller the angle of ascent of cam slots the bigger will be the magnitude of the backlash of the focus ring when the zoom motion reverses.

The advantage of the cam system is that it allows you to move more than one lens group by a nonlinear law of a motion at the same time. A front lens group is moved according to one law of motion and a rear lens group is moved on another one.

The disadvantage of such a design is the high manufacturing precision required because of manufacturing errors in the helical cam and backlashes in conjugations between cam tracks and cam followers.

Opto-mechanical Lens Focusing With Threaded Assembly

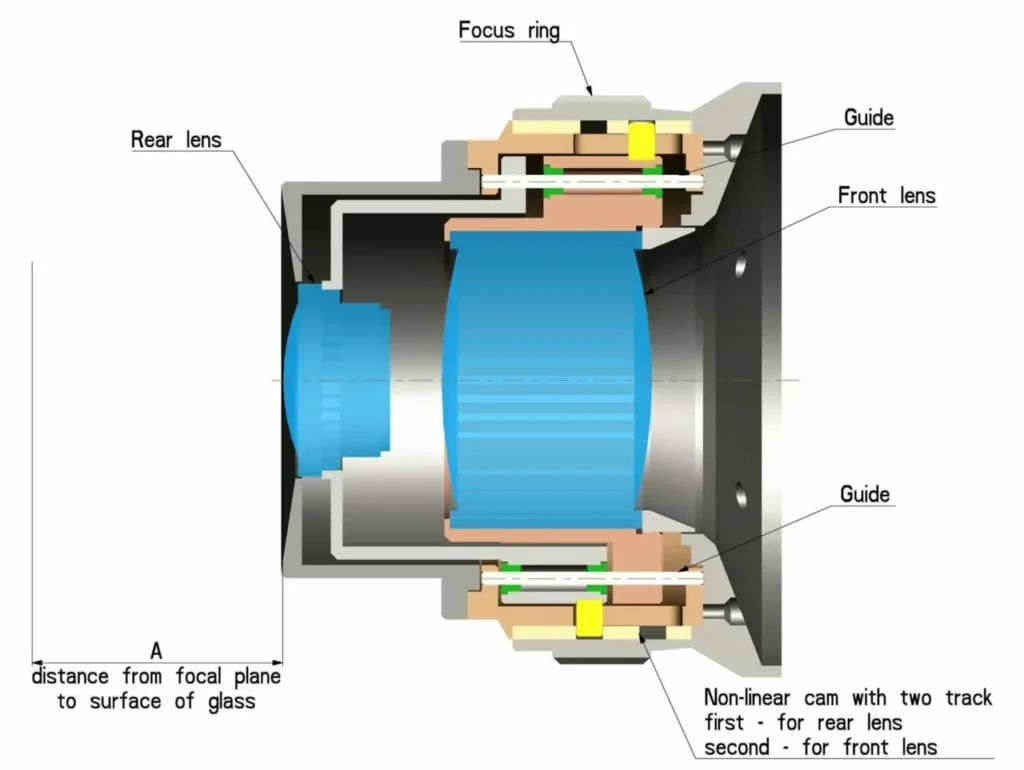

One of the most common mechanisms used in zoom and focusing systems is to move, relative to the focal plane, all the lens elements in an assembly.

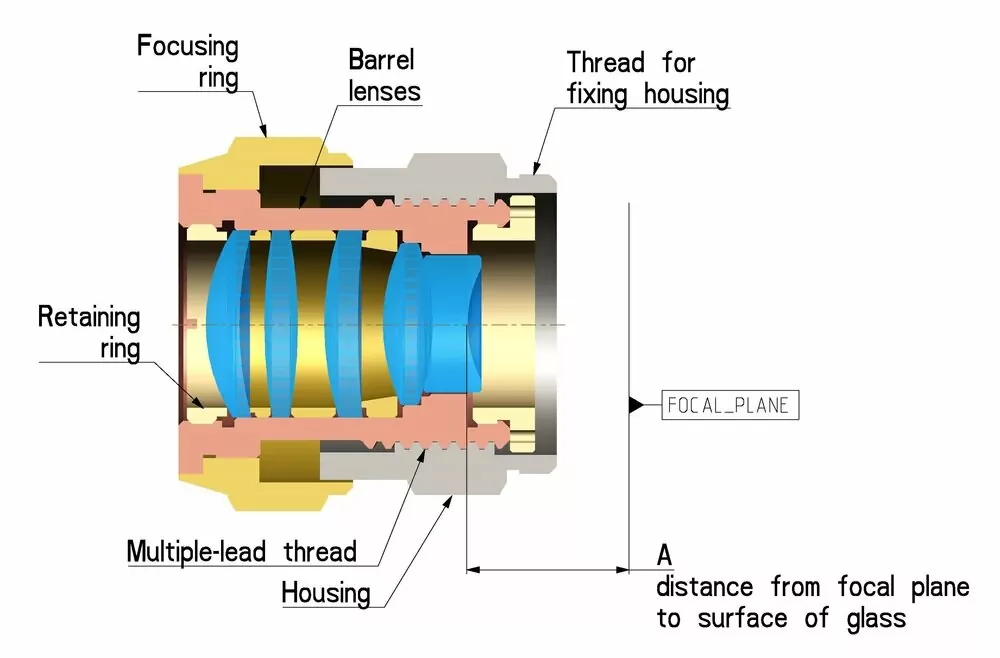

In the image below, changing distance “A” from focal plane to the first lens element is accomplished by turning a focusing ring.

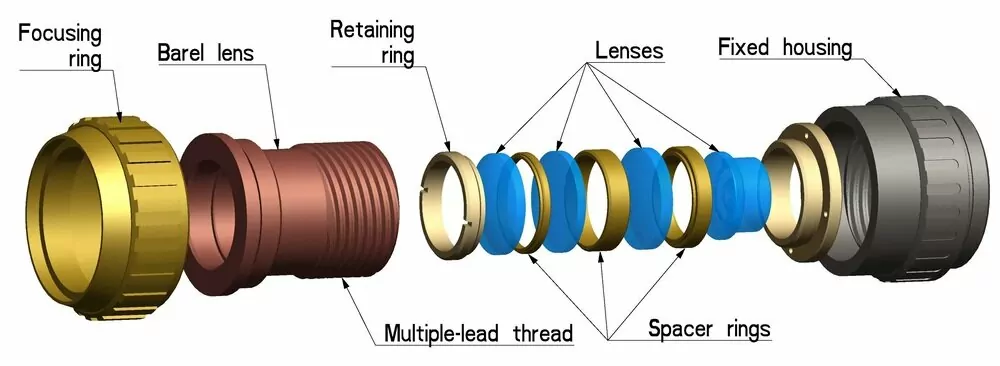

All lens elements are mounted into a barrel. Lenses are held in place relative to each other with a threaded retaining ring. This maintains the elements in the assembly distance, centration, and tilt constant.

Need help? Click here to learn more about our custom optical engineering services.

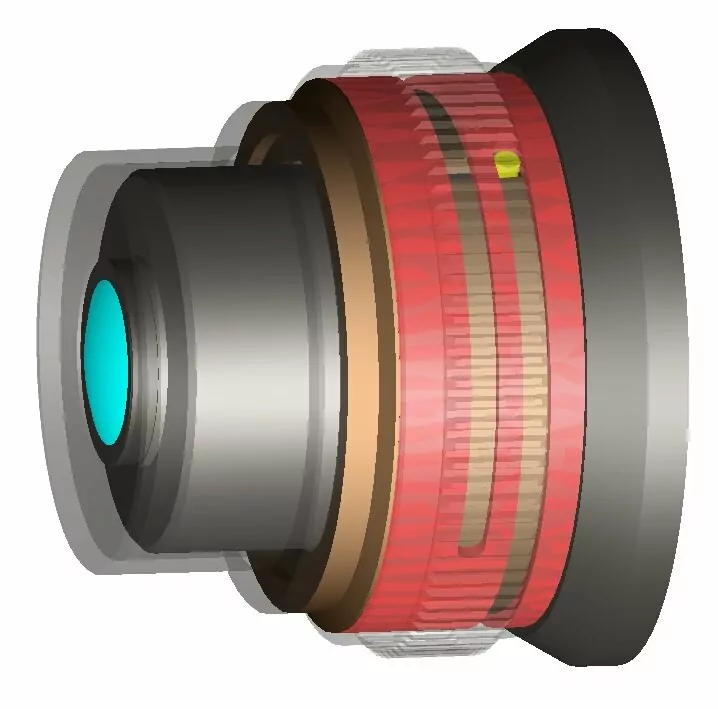

In the example below, we use a multiple-lead thread ( 4-8 individual coarse threads working in parallel) When the focusing ring is turned, the threads act together to axially move the lens sub-assembly.

The yellow retaining ring is screwed into the lens barrel to prevent unscrewing of the barrel during focusing.

If the lenses also rotate about the axis, the image will shift laterally while focusing. This can happen as a result of errors of lens and mechanical parts manufacturing or poor design.

To avoid this problem, the construction is made so that, with rotation of a focusing ring, the cell with lenses is moved only linearly.

Please see our next blog posts for a description of other common zoom/focusing mechanism.

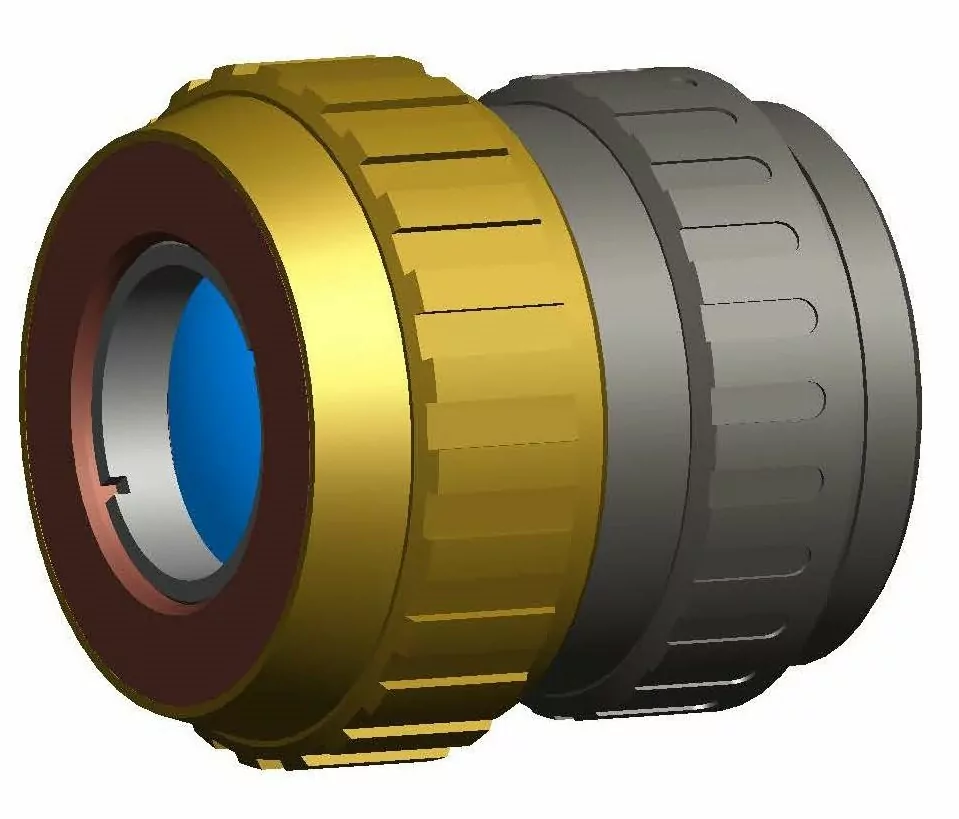

(The images below were prepared by Optics for Hire Engineer Viacheslav Lossik and may be used with attribution.)

Autofocus Opto- Mechanical Systems-One Approach

Autofocus camera technology is familiar in consumer, industrial, and medical applications, and it is easy to forget the complex mechanical and electronics system required to make it work well. One widely used method is described below.

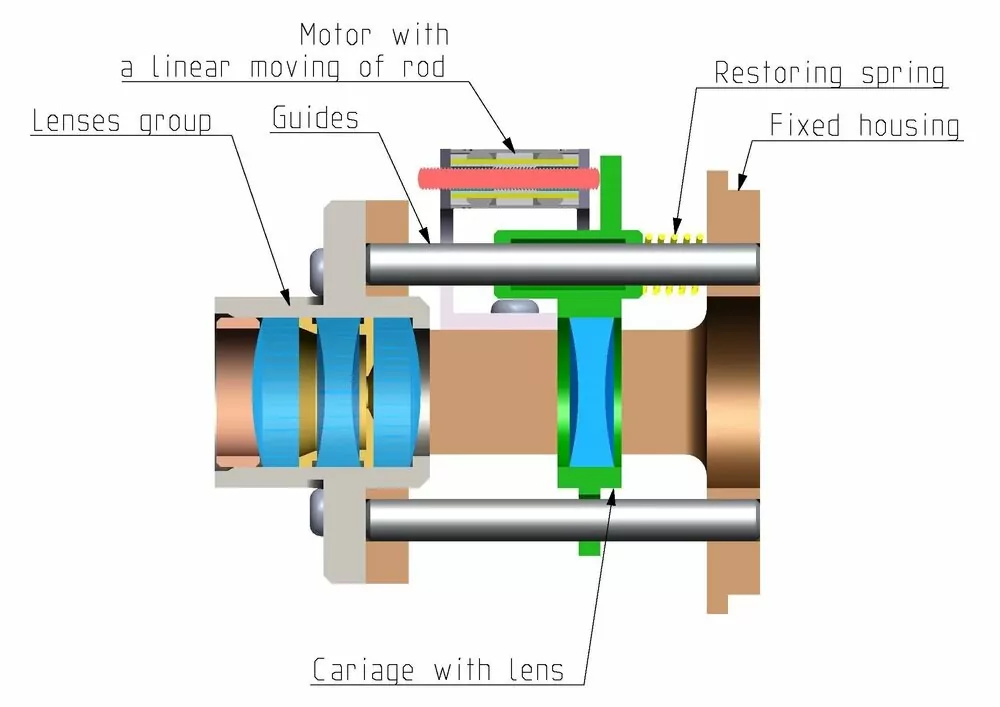

The basic idea is to change the distance from the lens to the light-sensitive surface (matrix or film) providing focus. This can be achieved by moving either the lens or the light-sensitive surface. Depending on the application, that movement is powered by an ultrasonic piezoelectric,stepper, or VCM motor.

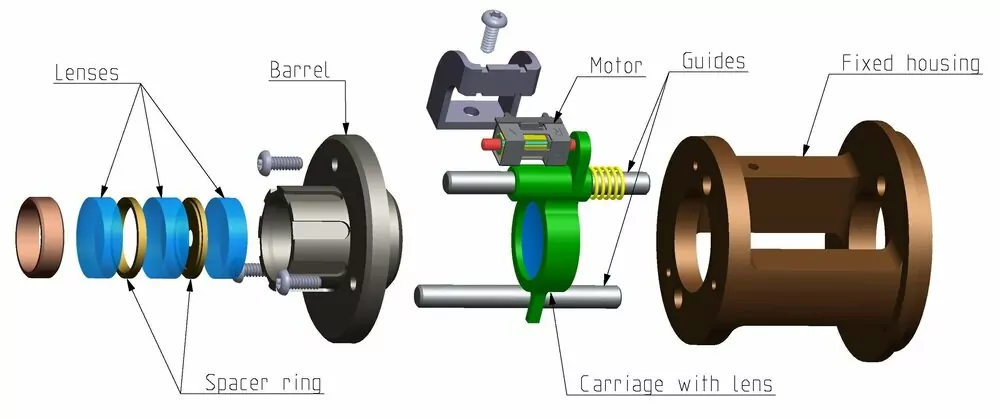

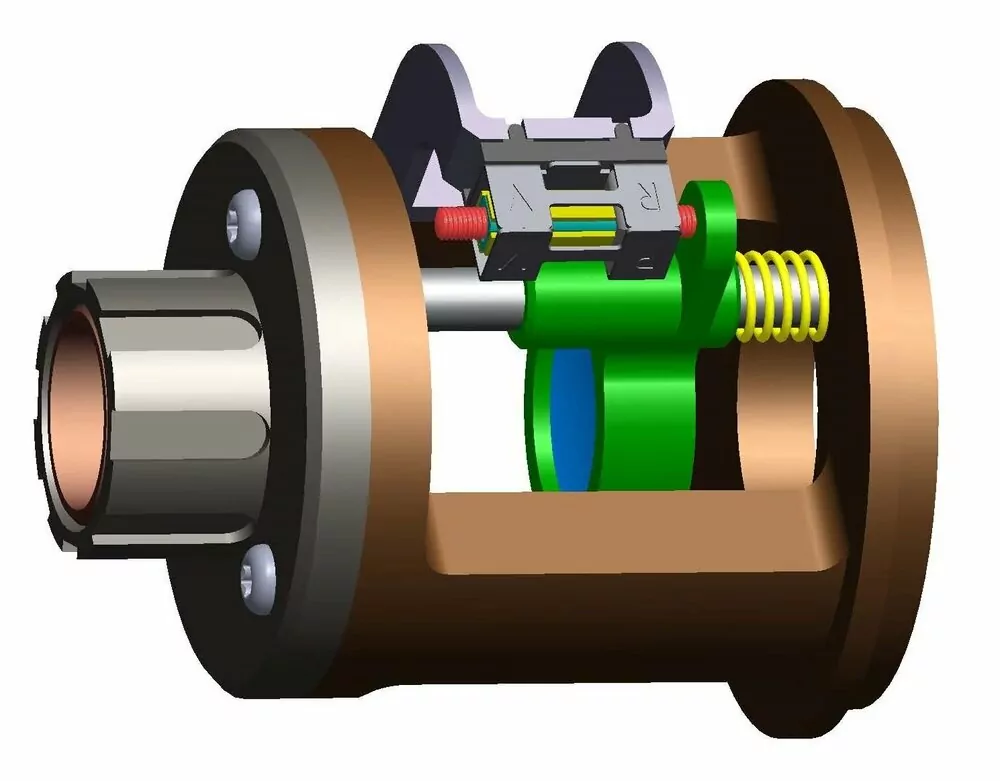

The images below show lens movement controlled by an actuator. The actuator creates linear movement of a rod and a return spring ensures a force-closure. This eliminates any gap between the rod and carriage. Two guides are used in this system to minimize dynamic and static lens carriage position errors. The support electronics for the actuator provide the signal analysis required to determine the correct position.

Need help? Click here to learn more about our custom optical engineering services.

Emerging Frontiers in Opto-Mechanical Engineering:

In the dynamic landscape of opto-mechanical engineering, cutting-edge trends and innovations are reshaping the possibilities of optical design.

Adaptive Optics Evolution: Adaptive optics is undergoing a transformative phase with advancements geared towards real-time correction of optical aberrations. This innovation is particularly critical in fields like astronomy, where the clarity of celestial observations is paramount, and in vision science, where precision is integral to laser eye surgeries and diagnostics. The integration of sophisticated algorithms and high-speed actuators is enabling adaptive optics systems to dynamically counteract atmospheric disturbances, leading to unprecedented image clarity and sharper focus.

Revolution in Miniaturization: Opto-mechanical engineering is witnessing a revolution in miniaturization, driven by breakthroughs in creating smaller, more precise optical components. This trend is catalyzing advancements in sectors ranging from telecommunications, where compact devices enhance data transmission efficiency, to medical devices, enabling minimally invasive procedures with improved imaging capabilities. The synthesis of lightweight yet high-performance materials contributes to the development of portable and versatile optical systems, expanding the reach of optical technologies.

Advanced Materials Integration: The integration of advanced materials, including metamaterials, is reshaping the landscape of opto-mechanical engineering. Metamaterials offer unprecedented control over light properties, paving the way for innovative optical devices with enhanced functionalities. Simultaneously, the incorporation of materials with superior mechanical strength is bolstering the durability and reliability of optical components. This intersection of material science and optics is opening avenues for designing robust systems that withstand diverse environmental conditions.

Revolutionizing Production with 3D Printing: The adoption of 3D printing in opto-mechanical engineering is revolutionizing the production of complex and customized components. Additive manufacturing techniques allow for the creation of intricate optical structures with a level of precision that was once challenging to achieve. This not only reduces production costs but also accelerates prototyping and customization processes, fostering innovation in the design and manufacturing of optical components.

Intelligent Systems with AI and Machine Learning: A paradigm shift is underway with the integration of artificial intelligence (AI) and machine learning in opto-mechanical systems. AI algorithms are being employed to optimize the design processes, predict system performance, and automate complex decision-making tasks. This intelligent integration enhances the efficiency of optical systems by adapting to changing conditions, optimizing configurations, and ultimately pushing the boundaries of what is achievable in optical design.

In this era of rapid technological evolution, these trends in opto-mechanical engineering collectively signify a transformative phase, promising advancements that not only enhance current capabilities but also open new frontiers for innovation and discovery. As researchers, engineers, and designers continue to explore these frontiers, the future of opto-mechanical engineering holds the promise of even more profound breakthroughs and applications across various industries.

Opto-Mechanical Design FAQ

Q: What are key components in opto-mechanical design?

A: Key components in opto-mechanical design include the integration of optical elements like lenses and mirrors with mechanical structures. This involves precise alignment, material selection, and consideration of environmental factors.

Q: How does opto-mechanical design impact optical system performance?

A: Opto-mechanical design is crucial for ensuring system stability, accuracy, and overall performance. It addresses the challenges of mounting optical components, managing thermal effects, and minimizing mechanical stresses that can affect optical quality.

Q: What are common challenges in opto-mechanical engineering?

A: Common challenges include managing the trade-offs between mechanical stability and optical performance, designing for manufacturability, and ensuring system reliability under various environmental conditions.