Ray sets

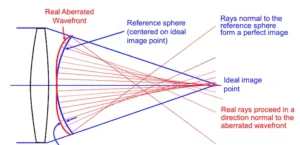

A rayset (sometimes called a rayfile) is a key element in the design of any illumination system. It describes the path of hundreds of thousands, millions, and even billions of rays of light as they leave a source (typically an LED). This data set is used in a ray tracing program like Zemax to design an optical system and to simulate how different designs would perform.

Most LED vendors including CREE, Lumileds, Nichia, and Osram, provide free raysets as part of their documentation. Vendors may use different names for the file, but the most common format for the file is prosource.

On this page for the CREE X-lamp XM3 you can see not only data sheets, bin details, mechanical CAD files but also the “optical source model” which contains the prosource raysets.

In some cases, we have needed to hire an optical metrology company (we use https://www.radiantvisionsystems.com) to create the prosource data set for us for more accurate modeling. This can cost $3,000- $5,000 . (NOTE: Recently I learned about a new supplier for raysets in Europe www.ilexa.de they seem to have a bit lower cost pricing)

Raysets often include spectral (color) data as well as the path of photons exiting an source.

It is possible to design without a rayset. In that case, the illumination engineers will need to either use the data sheet to make assumptions about the ray pattern or use an analogous rayset from an LED chip with similar properties. For the highest accuracy and most reliable design, a best practice is to use the rayset provided by the LED supplier.

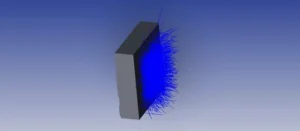

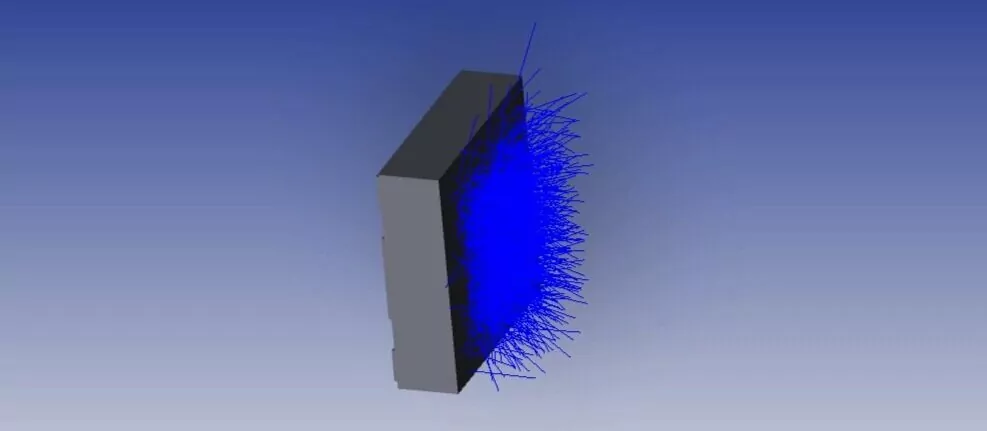

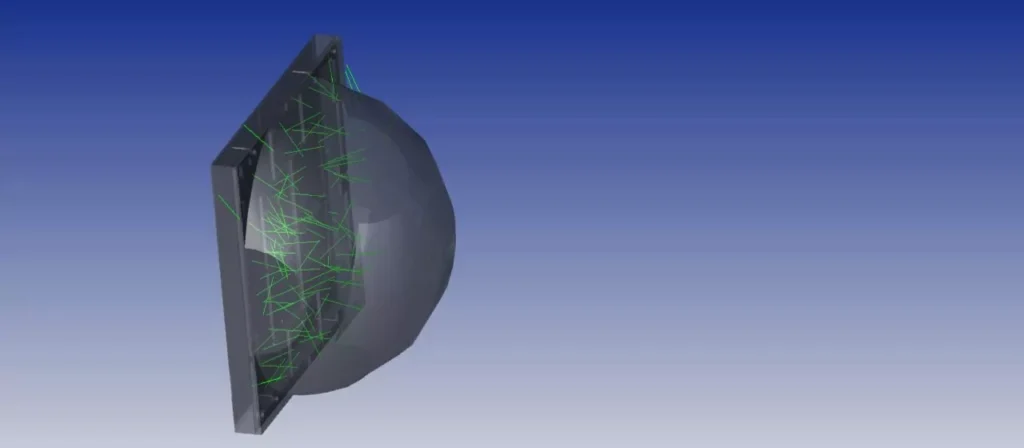

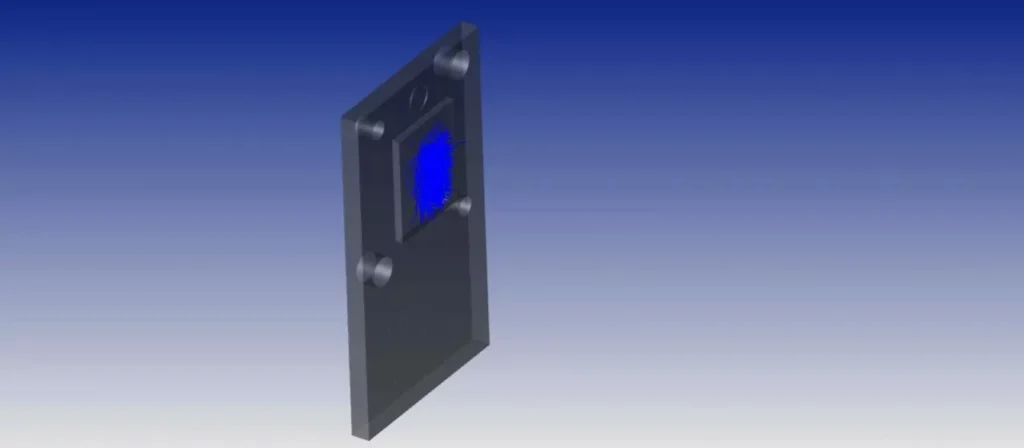

In general, the rayset is separate from the source solid model. For the sake clarity, we show in the images below both the solid model of the chip and the rays.

1000 rays on Cree XHP35HI

100 rays shown on a Cree XHP70

1000 rays shown on Osram PW3

Need help? Click here to learn about our optical engineering consulting services

Raysets provide engineers with an accurate representation of the dimensions and light patterns, helping to avoid confusion, such as the example described below with CREE data.

Example of Rayfile use, did Cree reps provide incorrect data? (it’s complicated)

Many of our LED optical design projects start with a simple calculation. Basically, we tell a client how much mechanical space they need to reserve for a lens to achieve the beam angle or pattern they want. In all cases, the larger the LED chip, the bigger the optic and the smaller the beam angle, the bigger the optic. Sometimes this presents a problem.

A key detail in the calculation is ‘how big is the emission area of the chip?’ As it turns out, this is not always a simple question. The reason is that some LED’s have encased optics that sit on top of the phosphor magnifying the emission area.

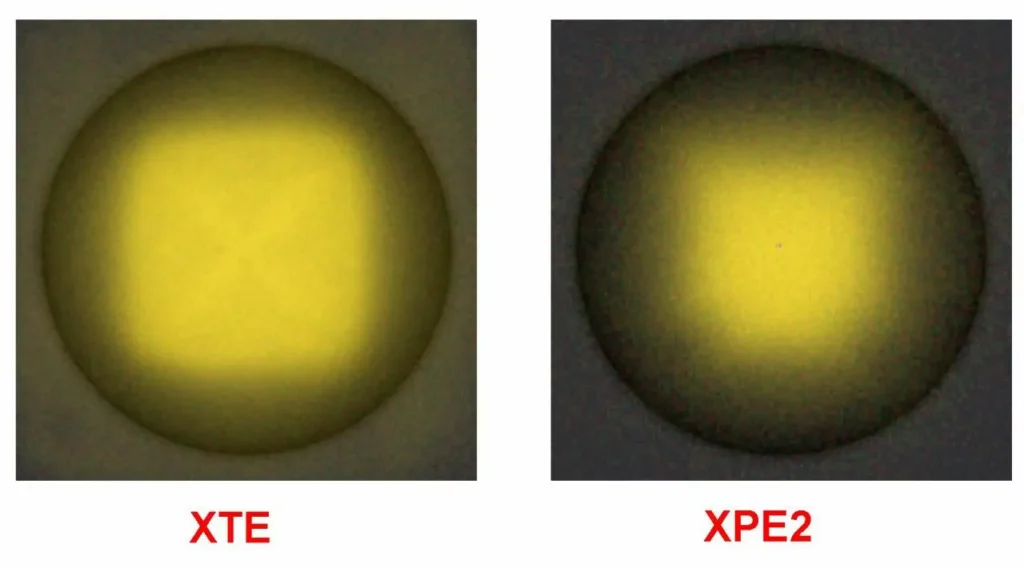

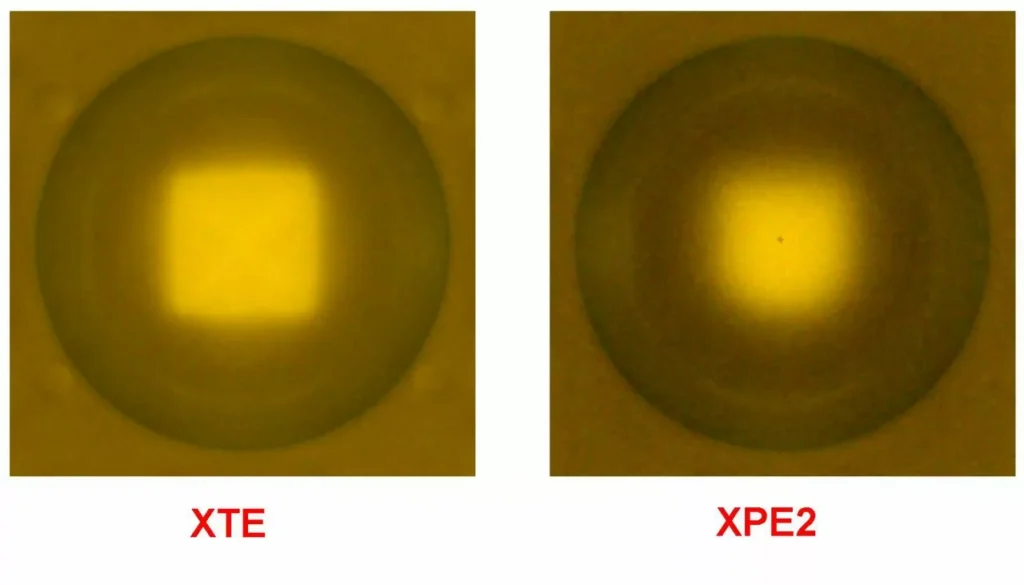

So every so often (it happened last week!) a client asks ” how big of an optic do we need to make our pattern with the CREE XTE or XPE2?”. We tell them “well, the XTE has about 2 x 2 mm, XPE2 has about 1.6 x 1.6mm emission area” after which the client hears from CREE “No! there is some mistake, OFH is confused XTE is a 1mm x 1mm.”

Why does this happen?

The two sets of images below show the XTE and XPE2 LED’s. The package size is the same but the left and right images have different phosphor sizes. Both of these LED’s have a lens on top and in the first image we see what the LED looks like in real life to a ray tracing program. The bottom image shows what the LED looks like if we ignore the lens on top.

What you will notice is in the top image, the emission area is larger than in the bottom image. For an optical engineers, the only data that matters is “where is the light when it hits my optic”. This is shown in the top image. While the bottom image shows light at the phosphor level is interesting, it is not helpful in determining how big a lens or reflector needs to be.

In effect neither CREE nor OFH is wrong: the phosphor is the size CREE says it is, but the LED emission area is functionally the size our engineers us, the rayfile helps sort out issues and problems like this.

Need help? Click here to learn more about our custom illumination optic design services.

Images may be used with permission. Data was prepared by Dr. Anatoli Trafimuk