In the dynamic landscape of industrial manufacturing, advancements in welding technologies continually push the boundaries of precision and efficiency. Among these innovations, wobble welding has become an essential technique, combining the power of industrial laser technology with scanning mirrors to redefine the possibilities of welding across various materials. In this article, we delve deep into the details of wobble welding, shedding light on its mechanisms, applications, and potential for transforming industrial welding processes.

Understanding the Fundamentals of Wobble Welding

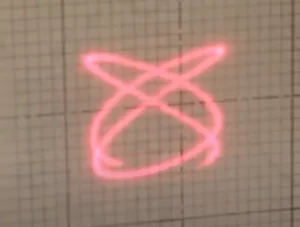

Wobble welding, also referred to as oscillating or circular welding, represents a departure from traditional welding methodologies. At its core, wobble welding introduces controlled oscillations to the laser beam during the welding process. By modulating the movement of an high power industrial laser beam, wobble welding creates a larger weld pool, facilitating enhanced heat distribution and mitigating common welding defects. This innovative approach results in superior weld quality, increased mechanical strength, and improved overall performance, making it an invaluable asset in a wide array of applications.

The Role of Laser Scanners: Precision in Motion

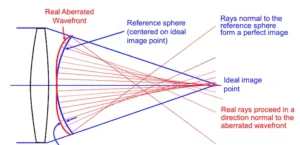

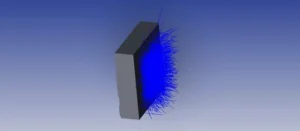

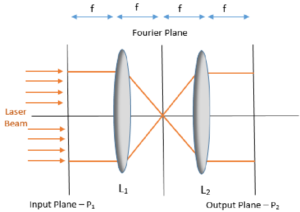

Central to the success of wobble welding are laser scanners, which serve as the primary mechanism for controlling the movement of the laser beam. We previously explored the idea of laser scanners. These scanners, equipped with advanced mirror configurations, enable precise modulation of the laser beam’s oscillation pattern. Through adjustments of parameters such as frequency, amplitude, and phase, manufacturers can achieve unparalleled control over the welding process, ensuring optimal results across diverse substrates and welding scenarios.

Deciphering the Dynamic Mechanism of Laser Wobble Control

Dynamic laser wobble control lies at the heart of wobble welding’s efficacy, empowering manufacturers to adapt and optimize the welding process in real-time. With feedback systems and advanced control algorithms, laser systems equipped with wobble welding capabilities can dynamically adjust the oscillation parameters to accommodate changing welding conditions. This dynamic responsiveness enhances weld quality, minimizes defects, and maximizes productivity, thereby elevating the overall efficiency and effectiveness of the welding process.

Versatility Across Substrates: Meeting Diverse Industrial Needs

Wobble welding stands as a beacon of versatility in the realm of industrial welding, offering a multifaceted solution capable of addressing the diverse needs of various substrates. From traditional metals like stainless steel, aluminum, and titanium to exotic materials such as silicon carbide, wobble welding demonstrates an unparalleled adaptability that empowers manufacturers across a spectrum of industries.

Stainless Steel:

Stainless steel, renowned for its corrosion resistance and durability, finds extensive applications across industries ranging from automotive to food processing. With wobble welding, manufacturers can tackle the challenges posed by stainless steel welding, achieving seamless joints with minimal distortion. Whether it’s thin gauge sheets or heavy structural components, wobble welding ensures consistent weld quality, preserving the integrity of stainless steel components in demanding environments.

Aluminum:

Aluminum, prized for its lightweight properties and high strength-to-weight ratio, is a staple material in aerospace, automotive, and marine applications. Wobble welding offers a precise and efficient method for joining aluminum components, overcoming common challenges such as porosity and distortion. By optimizing parameters such as oscillation frequency and beam focus, manufacturers can achieve robust aluminum welds with superior mechanical properties, meeting the stringent requirements of modern engineering applications.

Titanium:

Titanium, revered for its exceptional strength, corrosion resistance, and biocompatibility, finds extensive use in aerospace, medical, and chemical industries. Welding titanium presents unique challenges due to its reactive nature and susceptibility to contamination. However, wobble welding emerges as a reliable solution for titanium welding, delivering pristine welds with minimal heat-affected zones and metallurgical defects. With precise control over oscillation parameters, manufacturers can ensure the integrity of titanium components, enabling the realization of complex and lightweight structures in critical applications.

Exotic Materials such as Silicon Carbide:

Exotic materials like silicon carbide, characterized by their extreme hardness, thermal stability, and excellent electrical conductivity, are gaining prominence in advanced industries such as semiconductor manufacturing and high-temperature applications. Wobble welding offers a tailored approach for joining silicon carbide components, leveraging its dynamic control capabilities to navigate the unique challenges posed by these materials. By optimizing parameters such as beam intensity and dwell time, manufacturers can achieve robust silicon carbide welds, facilitating the development of next-generation electronic devices and cutting-edge industrial equipment.

Composite Materials:

In addition to traditional metals and exotic materials, wobble welding demonstrates remarkable efficacy in joining composite materials, such as carbon fiber reinforced polymers (CFRP) and fiberglass. These lightweight and high-strength materials are prevalent in industries ranging from aerospace and automotive to renewable energy. Wobble welding provides a precise and efficient method for bonding composite components, enabling the fabrication of lightweight structures with superior mechanical properties and structural integrity.

Empowering Manufacturers with Confidence:

In essence, the versatility of wobble welding pair with industrial lasers transcends the boundaries of material complexity and geometry, offering manufacturers a reliable and adaptable solution for their welding needs. Whether faced with the challenges of traditional metals, exotic materials, or composite structures, wobble welding empowers manufacturers to tackle complex welding tasks with confidence, knowing that consistent, high-quality welds can be achieved across diverse substrates and applications. As industries continue to evolve and innovate, wobble welding stands as a testament to the transformative power of advanced welding technologies in driving industrial progress and shaping the future of manufacturing.

Optimizing Performance: Key Specifications and Considerations

To harness the full potential of wobble welding, meticulous attention to detail is essential. Key specifications, such as beam size and power density, play a critical role in determining the welding system’s performance and capabilities:

– Beam Size: Typical laser beam diameters ranging from 10mm to 30mm, wobble welding accommodates a diverse range of welding scenarios, from micro-welds to large-scale applications. The ability to adjust the beam size allows manufacturers to tailor the welding process to suit specific requirements and geometries.

– Power Density: Operating at an 4000 W/cm² or more, wobble welding delivers the intense energy required for rapid and precise fusion. This high power density ensures efficient heat generation and penetration, resulting in robust, high-quality welds across a wide range of materials and thicknesses.

– Continuous Wave (CW) Operation: With a 1070nm wavelength and 5KW power output, CW operation ensures sustained performance for prolonged welding tasks. This continuous energy delivery enables manufacturers to achieve consistent weld quality and productivity, even during extended welding sessions.

Embracing the Future of Welding: Innovations and Opportunities

In conclusion, wobble welding represents a paradigm shift in industrial welding, offering unparalleled precision, efficiency, and vesatility. By leveraging laser technology and advanced scanner dynamics, manufacturers can unlock new possibilities in welding, from automotive and aerospace applications to electronics and medical devices. As industries evolve and demand for high-quality welds continues to grow, wobble welding stands poised to play a pivotal role in shaping the future of manufacturing, driving innovation, and propelling industrial progress to new heights.

Frequently Asked Questions (FAQ) about Wobble Welding:

What is wobble welding, and how does it differ from traditional welding methods?

Wobble welding is a technique that introduces controlled oscillations to the laser beam during the welding process. This oscillation creates a larger weld pool, facilitating enhanced heat distribution and mitigating common welding defects. Unlike traditional welding methods, wobble welding offers superior weld quality, increased mechanical strength, and improved overall performance across various substrates.

What types of materials can be welded using wobble welding?

Wobble welding demonstrates versatility across a wide range of materials, including metals like stainless steel, aluminum, and titanium, as well as exotic materials such as silicon carbide. Additionally, wobble welding is effective for joining composite materials like carbon fiber reinforced polymers (CFRP) and fiberglass.

How does laser scanning technology contribute to the effectiveness of wobble welding?

Laser scanning technology, particularly advanced mirror configurations like the Cyclops single mirror scanner, plays a crucial role in controlling the movement of the laser beam during wobble welding. By precisely modulating parameters such as frequency, amplitude, and phase, laser scanners ensure optimal weld characteristics, resulting in superior weld quality and consistency.

What are the key benefits of using wobble welding in industrial applications?

Wobble welding offers several key benefits, including enhanced weld quality, increased mechanical strength, and improved heat distribution. Additionally, wobble welding enables manufacturers to achieve consistent and reliable welds across diverse substrates and geometries, leading to greater productivity, reduced rework, and overall cost savings.