White Papers

“What does better mean in engineering?”

As an engineering services provider, we frequently encounter a question that can come up in any business organization.

It may seems simple but to answer it successfully, an organization should account for different perspectives between stake holders in management, marketing, and engineering functions.

We’ve collected some of the divergent attitudes to product specifications, cost, schedule, road maps, and design concepts we have encountered over the years. Depending on the situation, these attitudes are neither right nor wrong. We try to understand the meaning behind ‘better’.

How do I know if a lens is well-matched to a sensor?

Are you designing a system that includes an objective lens and an image sensor? Are you trying to choose a digital camera as a gift, and not sure if you should simply buy the one with the most megapixels? We’ll show you that an optical system is usually only as strong as its weakest link. Whether it’s an ordinary camera or a complex imaging system, you’ll be happier if its detector is well-matched to its imaging optics, such as the objective lens.

The article may be reprinted with attribution.

Case studies

Past projects described:

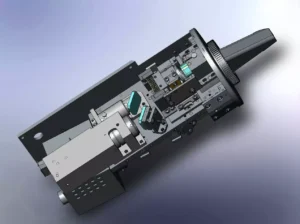

Starting in the late 1970s, engigneers from OFH led programs creating equivalents of the laser disc, CD, and CDR formats. These were commercialized in the former USSR.

By the late 1990s, these same engineers worked on multi layer optical media drives for the former Constellation 3D and in the 2000’s we used those skills for Holigraphic data storage and the LaserCard format.

This case study describes some of the key technologies developed by the optical design team during their work on optical data storage

The edge break sensor is a compact handheld optical sensor prototype used to identify micron sized defects without the time consuming processing of taking a wax mold and measuring that mold on a profilometer.

It works by projecting a pattern of lines onto the region of interest and then capturing images of that pattern which can be used to extract surface profile information.

How do I know if a lens is well-matched to a sensor?

Are you designing a system that includes an objective lens and an image sensor? Are you trying to choose a digital camera as a gift, and not sure if you should simply buy the one with the most megapixels? We’ll show you that an optical system is usually only as strong as its weakest link. Whether it’s an ordinary camera or a complex imaging system, you’ll be happier if its detector is well-matched to its imaging optics, such as the objective lens.

The article may be reprinted with attribution.

Case studies

Three past projects described:

Get in Touch

Fill out the form below or contact us directly.

Call Us

To discuss your project

781-583-7810

Email Us

We are ready to assist